Cleaning Solar Panels Without Water

How To Clean Your Solar Panels Without Water

If you own a solar system, you’ll be glad to know that there’s a new cleaning technique that could help remove dust from water-limited regions of your installation, helping improve the system’s overall efficiency.

Experts anticipate that solar power will reach 10% of global power generation by 2030, with most of the energy being harvested in desert areas where there is plenty of sunlight. However, since the accumulation of dust on solar mirrors or panels is something that’s been known to reduce photovoltaic panel output by up to 30% in a month, regular cleaning is crucial for these installations.

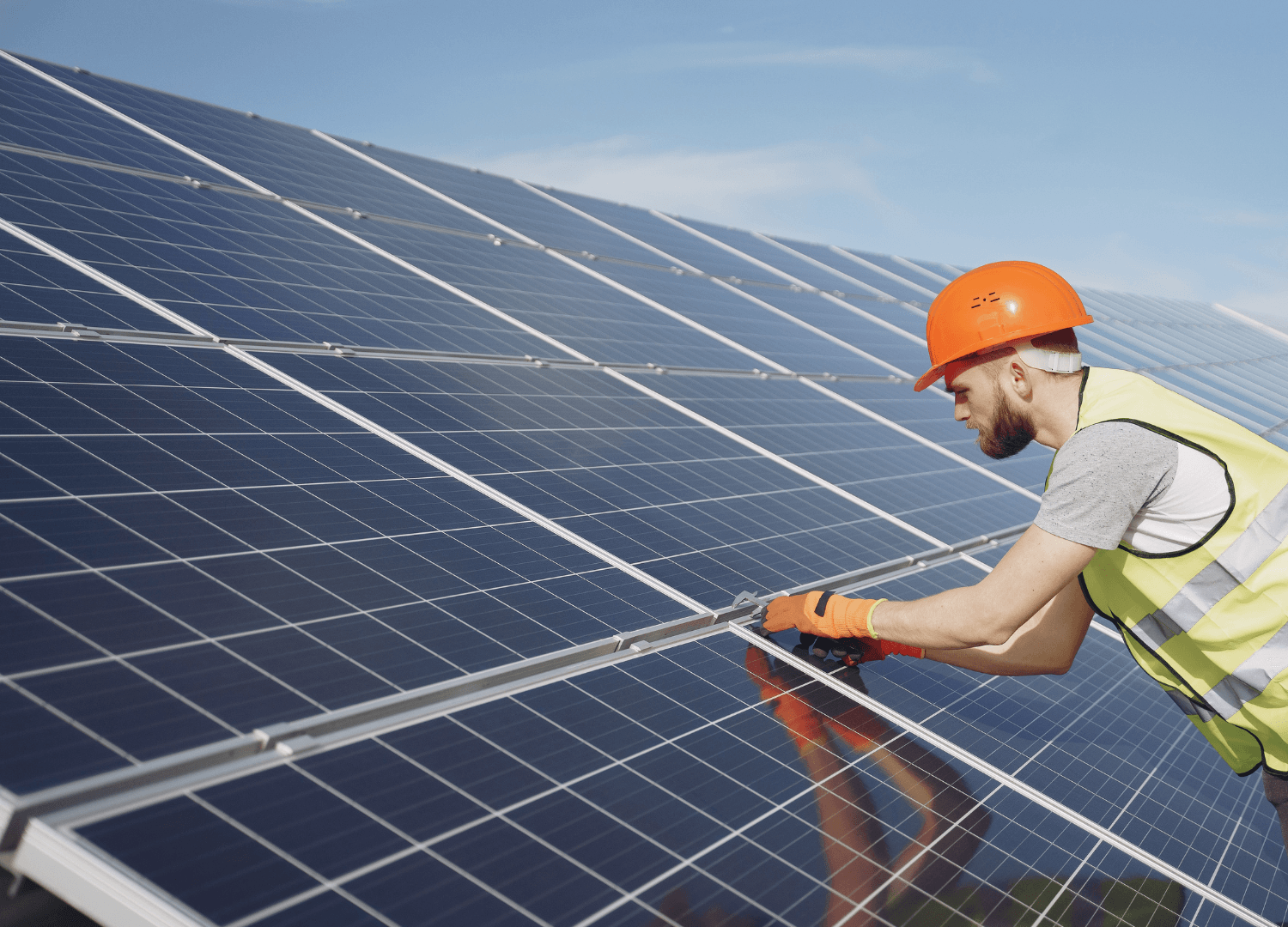

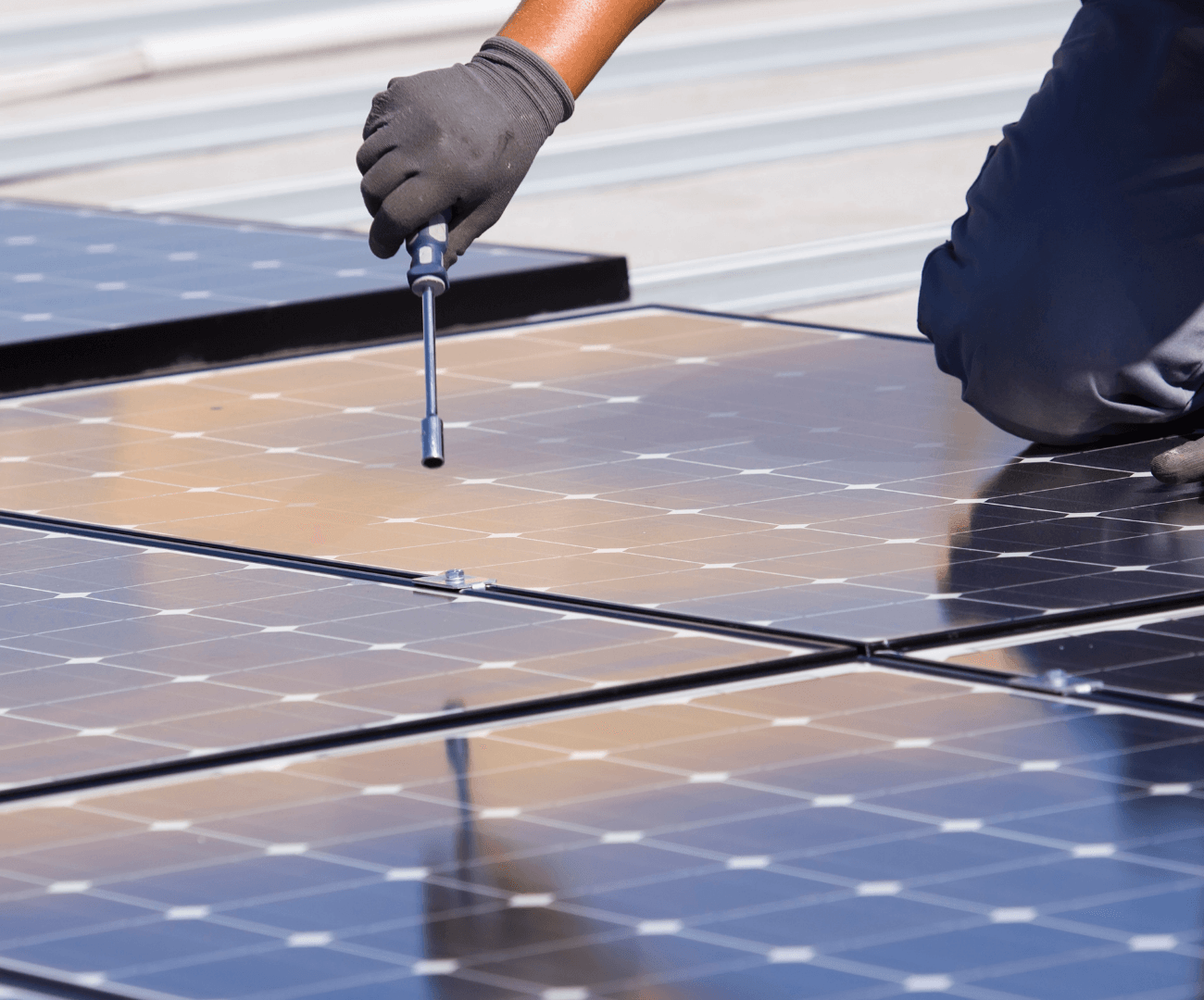

While cleaning solar panels is essential to improving their efficiency, the process can be quite wasteful considering that they use up about 10 billion gallons of water annually – enough to supply clean drinking water for a whole city. While there have been attempts to make the process waterless, the problem with this is that the process can be quite labor-intensive and tends to cause permanent scratches on the surface of the panel, reducing efficiency.

Fortunately, however, a team of researchers at the Massachusetts Institute of Technology have come up with a no-contact, waterless cleaning solution that automates the process of cleaning solar mirrors and panels, significantly reducing the dust problem.

Using electrostatic repulsion, the new system causes particles of dust to detach and leap off the surface of the solar panel without the need for brushes or water. The system uses an electrode that passes right above the surface of the solar panel, imparting electrical charges to particles of dust on the panel. At the same time, a charge is applied to the panel itself, effectively repelling particles from its surface.

The good thing about this cleaning solution is that it can be operated automatically using guide rails set along the sides of a solar panel and a simple electric motor. The technology is explained in more detail in the journal “Science Advances” (March 11, 2022) in a paper by Professor Kripa Varanasi, professor of mechanical engineering, and Sreedath Panat, an MIT graduate student.

Despite many people from around the world putting a lot of effort to develop efficient solar panels, laboratory tests conducted by Varanasi and Panat showed that the drop in energy output from solar panels occurs steeply once dust starts to accumulate and can easily hit a 30% reduction within a month if not cleaned. According to the team, even a 1% reduction in power for a 150-megawatt system could result in $200,000 in lost revenue annually. The two believe that a 3 to 4% reduction in global solar power output could amount to losses of over $3 to $5 billion annually.

A vast majority of the world’s largest solar power installations, including the ones in the U.A.E, India, the U.S., and China are located in deserts. Water used to clean solar panels generally has to be transported from quite some distance to the site of the plant and has to be extremely clean to ensure that no deposits are left on the panels. While some installations use dry scrubbing to clean their panels, this option is less effective and may cause permanent scratches that may lead to a reduction of light transmission.

Cleaning using water makes up about 10% of the costs of operating a solar installation. This new system could hypothetically reduce operating costs while improving output as it makes it easier to clean panels more often.

Other research teams have tried developing electrostatic-based solutions but most of them use a layer of the electrodynamic screen with interdigitated electrodes. According to Varanasi, since these panels allow moisture to get in, they are more susceptible to failure. While they are perfect for use in a moisture-free environment like Mars, they aren’t as practical here on Earth, where even in dry environments like deserts, moisture is still an issue.

The only thing their new solar panel cleaning system requires is an electrode (a simple metal bar will do) to pass over the surface of the panel producing electric fields that impart a charge to particles of dust as it moves along. An opposite charge, which is applied to a nanometers-thick conductive and transparent layer covering the panel, repels the particles. After calculating how much voltage would be needed to make the system work, the team was able to come up with a voltage range that’s sufficient enough to overcome adhesion forces and the pull of gravity and cause particles to lift away from the panel.

Using specially-prepared lab samples of dust in varying sizes, tests proved the process effective on lab-scale test installations according to Panat. Tests also showed that moisture in the air would coat dust particles, which proved to be useful to make the process work.

In reality, at scale, each panel of a solar system could be fitted with a railing system on either side with electrodes spanning across the panes. A tiny electric motor, possibly using a small amount of the output from the solar system itself, can be used to drive a belt system and move the railing system holding the electrodes across the panel causing dust particles to fall off. The process can either be remotely controlled or automated. Alternatively, very thin strips of a transparent yet conductive material could be permanently arranged above the surface of the solar panel, removing the need for moving parts.